Question: FB Badpoore Aerospace makes carbon brake discs

FB Badpoore Aerospace makes carbon brake discs for large airplanes with a proprietary “cross weave†of the carbon fibers. The brake discs are 4 feet in diameter but weigh significantly less than conventional ceramic brake discs, making them attractive for airplane manufacturers, as well as commercial airliners.

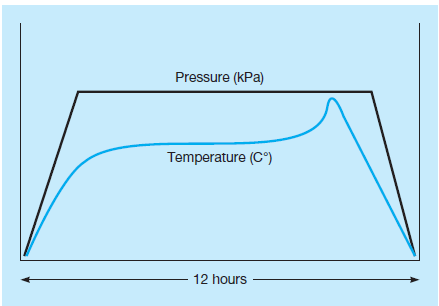

Processing the discs at FB Badpoore requires heat treating the discs in a sequence of 12 electric, high pressure, industrial grade furnaces (simply called Furnace A, Furnace B, Furnace C, . . . , Furnace L), each of them fed with a proprietary mixture of chemicals. All brake discs visit each of the 12 furnaces in the same order, Furnace A through Furnace L. Each of these furnaces follows its own very specific set of simultaneous temperature and pressure profiles. An example of one such profile is depicted in Figure 13.6. All profiles are 12 hours in duration.

All 12 furnaces are top loading. Additionally, each of them is cylindrical in shape, 15 feet in diameter, and about 10 feet in depth. They are arranged in an “egg-carton-like†array (six on one side and six on the other), loaded and unloaded via their top facing round ends by three overhead 10-ton bridge cranes, and located in part of the factory known as the furnace deck.

Each furnace can process seven stacks of 20 discs at a time. This equates to a batch size of 140 discs. Each batch is loaded onto a ceramic furnace shelf that is sturdy, round, and 14 feet in diameter. The furnace deck is said to be fully loaded when all 12 furnaces are processing discs.

Loading and unloading the discs is a labor-intensive process requiring high-level coordination of the three overhead bridge cranes. Bridge crane Alpha (BC-A) serves the incoming area; furnaces A, B, K, and L; and the outgoing area, where discs are stored when they have finished processing in all 12 furnaces. Bridge crane Beta (BC-B) serves Furnaces C, D, I, and J, while bridge crane Gamma (BC-G) serves Furnaces E, F, G, and H. When discs travel within a service area, they are moved by the crane assigned to that area. When discs have to travel between service areas, they are first deposited in a waiting area before being moved into the next service area. For example, discs being moved from Furnace D to Furnace E would be unloaded from Furnace D by BC-B, which would deposit them in the waiting area. Then BC-G would pick up the batch and load it into (an already empty) Furnace E.

Due to energy restrictions by the local electric utility company, all furnace processing must be performed at night between 8:00 p.m. and 10:00 a.m. daily. This, in turn, requires all loading and unloading operations to be performed during the day. Indeed, the main shift is from 1:00 p.m. (allowing the discs to cool after processing and before unloading) and 9:00 p.m. (allowing the shift to end by starting up all 12 furnaces after 8:00 p.m.).

Figure 13.6:

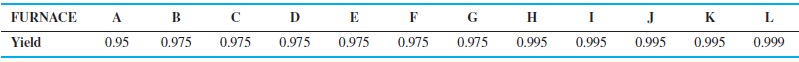

Each furnace has a known yield rate with no noticeable variation according to the following:

That is to say, 1 in 20 batches fails at Furnace A and must be scrapped, whereas only 1 in 1,000 batches fails at Furnace L. As one might expect, upstream batch failures are very disruptive to the downstream operations. Scrapping batches causes downstream furnaces to sit idle under the current “zero in queue†work in process (WIP) inventory policy as they wait for good batches to arrive from upstream operations. Design, build, and perform a 1,000-day simulation model study of the system described above in Excel, incorporating the random number generator function, RAND(). Start your simulation with a fully loaded furnace deck.

Discussion Questions

1. Determine and comment on the overall yield (the number of batches that make it all the way through Furnace L divided by the number that started at Furnace A) of disc brakes at FB Badpoore.

2. Determine the utilization of Furnace L.

3. Suggest improvements to the system.

Transcribed Image Text:

Pressure (kPa) Temperature (C°) 12 hours FURNACE A В C D E F H I J K L Yield 0.95 0.975 0.975 0.975 0.975 0.975 0.975 0.995 0.995 0.995 0.995 0.999

> The Bender Construction Co. is involved in constructing municipal buildings and other structures that are used primarily by city and state municipalities. This requires developing legal documents, drafting feasibility studies, obtaining bond ratings, and

> Bowman Builders manufactures steel storage sheds for commercial use. Joe Bowman, president of Bowman Builders, is contemplating producing sheds for home use. The activities necessary to build an experimental model and related data are given in the follow

> General Foundry’s project crashing data are shown in Table 11.9. Crash this project to 13 weeks using CPM. What is the final time for each activity after crashing? Table 11.9: TIME (WEEKS) COST ($) CRASH COST CRITICAL АCTIVITY NORMA

> How can we determine the probability that a project will be completed by a certain date? What assumptions are made in this computation?

> Fred Ridgeway has been given the responsibility of managing a training and development program. He knows the earliest start time, the latest start time, and the total cost for each activity. This information is given in the following table: (a). Using e

> The air pollution project discussed in the chapter has progressed over the past several weeks, and it is now the end of week 8. Lester Harky would like to know the value of the work completed, the amount of any cost overruns or under runs for the project

> Using PERT, Ed Rose was able to determine that the expected project completion time for the construction of a pleasure yacht is 21 months and the project variance is 4. (a). What is the probability that the project will be completed in 17 months or les

> Tom Schriber, the director of personnel of Management Resources, Inc., is in the process of designing a program that its customers can use in the job-finding process. Some of the activities include preparing resumés, writing letters, making

> A project was planned using PERT with three time estimates. The expected completion time of the project was determined to be 40 weeks. The variance of the critical path is 9. (a). What is the probability that the project will be finished in 40 weeks or

> After consulting with Butch Radner, George Monohan was able to determine the activity times for constructing the weed-harvesting machine to be used on narrow rivers. George would like to determine ES, EF, LS, LF, and slack time for each activity. The tot

> Sid Davidson was able to determine the activity times for the leadership training program. He would like to determine the total project completion time and the critical path(s). The activity times appear in the following table (see Problem 11-12): ACTIV

> The integer programming problem below has been developed to help First National Bank decide where, out of 10 possible sites, to locate four new branch offices: Xi represents Winter Park, Maitland, Osceola, Downtown, South Orlando, Airport, Winter Garden,

> Mick Garcia, a certified financial planner (CFP), has been asked by a client to invest $250,000. This money may be placed in stocks, bonds, or a mutual fund in real estate. The expected return on investment is 13% for stocks, 8% for bonds, and 10% for re

> Major Bill Bligh, director of the Army War College’s new 6-month attaché training program, is concerned about how the 20 officers taking the course spend their precious time while in his charge. Major Bligh recognizes that there are 168 hours per week an

> If you were the president of the college you are attending and were employing goal programming to assist in decision making, what might your goals be? What kinds of constraints would you include in your model?

> Hilliard Electronics produces specially coded computer chips for laser surgery in 64MB, 256MB, and 512MB sizes. (1MB means that the chip holds 1 million bytes of information.) To produce a 64MB chip requires 8 hours of labor, a 256MB chip takes 13 hours,

> Solve Problem 10-21. Are any goals unachieved in this solution? Explain. Problem 10-21: Geraldine Shawhan is president of Shawhan File Works, a firm that manufactures two types of metal file cabinets. The demand for her two-drawer model is up to 600 cab

> Geraldine Shawhan is president of Shawhan File Works, a firm that manufactures two types of metal file cabinets. The demand for her two-drawer model is up to 600 cabinets per week; the demand for a three-drawer cabinet is limited to 400 per week. Shawhan

> The campaign manager for a politician who is running for reelection to a political office is planning the campaign. Four ways to advertise have been selected: TV ads, radio ads, billboards, and social media advertising buys. The costs of these are $900 f

> Triangle Utilities provides electricity for three cities. The company has four electric generators that are used to provide electricity. The main generator operates 24 hours per day, with an occasional shutdown for routine maintenance. Three other genera

> A real estate developer is considering three possible projects: a small apartment complex, a small shopping center, and a mini-warehouse. Each of these requires different funding over the next 2 years, and the net present values of the investments also v

> Innis Construction Company specializes in building moderately priced homes in Cincinnati, Ohio. Tom Innis has identified eight potential locations to construct new single-family dwellings, but he cannot put up homes on all of the sites because he has onl

> Horizon Wireless, a cellular telephone company, is expanding into a new era. Relay towers are necessary to provide wireless telephone coverage to the different areas of the city. A grid is superimposed on a map of the city to help determine where the tow

> An airline owns an aging fleet of Boeing 737 jet airplanes. It is considering a major purchase of up to 17 new Boeing model 787 and 767 jets. The decision must take into account numerous cost and capability factors, including the following: (1) the air

> Student Enterprises sells two sizes of wall posters, a large 3- by 4-foot poster and a smaller 2- by 3-foot poster. The profit earned from the sale of each large poster is $3; each smaller poster earns $2. The firm, although profitable, is not large; it

> What are the earliest activity start time and latest activity start time? How are they computed?

> A group of college students is planning a camping trip during the upcoming break. The group must hike several miles through the woods to get to the campsite, and anything that is needed on this trip must be packed in a knapsack and carried to the campsit

> Elizabeth Bailey is the owner and general manager of Princess Brides, which provides a wedding planning service in southwestern Louisiana. She uses radio advertising to market her business. Two types of ads are available—those during prime-time hours and

> Hard rock Concrete’s owner has decided to increase the capacity at his smallest plant (see Problem 9.8). Instead of producing 30 loads of concrete per day at plant 3, that plant’s capacity has been doubled to 60 loads.

> The Hard rock Concrete Company has plants in three locations and is currently working on three major construction projects, each located at a different site. The shipping cost per truckload of concrete, daily plant capacities, and daily project require

> The management of the Executive Furniture Corporation decided to expand the production capacity at its Des Moines factory and to cut back the production capacities at its other two factories. It also recognizes a shifting market for its desks and revises

> Four automobiles have entered Bubba’s Repair Shop for various types of work, ranging from a transmission overhaul to a brake job. The experience level of the mechanics is quite varied, and Bubba would like to minimize the time required to complete all of

> In a job shop operation, four jobs may be performed on any of four machines. The hours required for each job on each machine are presented in the following table. The plant supervisor would like to assign jobs so that total time is minimized. Find the be

> Using the data from Problem 9-20 plus the unit production costs shown in the following table, which locations yield the lowest cost? LOCATION PRODUCTION COSTS Decatur …………

> Don Levine Corporation is considering adding an additional plant to its three existing facilities in Decatur, Minneapolis, and Carbondale. Both St. Louis and East St. Louis are being considered. Evaluating only the transportation costs per unit, as shown

> Marc Smith, vice president for operations of HHN, Inc., a manufacturer of cabinets for telephone switches, is constrained from meeting the 5-year forecast by limited capacity at the existing three plants. These three plants are Waterloo, Pusan, and Bogot

> Briefly discuss what is meant by critical path analysis. What are critical path activities, and why are they important?

> Ashley’s Auto Top Carriers currently maintains plants in Atlanta and Tulsa that supply major distribution centers in Los Angeles and New York. Because of an expanding demand, Ashley has decided to open a third plant and has narrowed the

> The J. Mehta Company’s production manager is planning for a series of 1-month production periods for stainless steel sinks. The demand for the next 4 months is as follows: MONTH DEMAND FOR STAINLESS STEEL SINKS 1 ……………………………………………………… 120 2 ………………………………

> The B. Hall Real Estate Investment Corporation has identified four small apartment buildings in which it would like to invest. Mrs. Hall has approached three savings and loan companies regarding financing. Because Hall has been a good client in the past

> The three blood banks in Franklin County are coordinated through a central office that facilitates blood delivery to four hospitals in the region. The cost to ship a standard container of blood from each bank to each hospital is shown in the table on thi

> The state of Missouri has three major power-generating companies (A, B, and C). During the months of peak demand, the Missouri Power Authority authorizes these companies to pool their excess supply and to distribute it to smaller, independent power compa

> Finnish Furniture manufactures tables in facilities located in three cities—Reno, Denver, and Pittsburgh. The tables are then shipped to three retail stores located in Phoenix, Cleveland, and Chicago. Management wishes to develop a dist

> Northwest University is in the process of completing a computer bus network that will connect computer facilities throughout the university. The prime objective is to string a main cable from one end of the campus to the other (nodes 1–

> An air-conditioning manufacturer produces room air conditioners at plants in Houston, Phoenix, and Memphis. These are sent to regional distributors in Dallas, Atlanta, and Denver. The shipping costs vary, and the company would like to find the least-cost

> South Side Oil and Gas, a new venture in Texas, has developed an oil pipeline network to transport oil from exploration fields to the refinery and other locations. There are 10 pipelines (branches) in the network. The oil flow in hundreds of gallons and

> The Oakton River had long been considered an impediment to the development of a certain medium-sized metropolitan area in the Southeast. Lying to the east of the city, the river made it difficult for people living on its eastern bank to commute to jobs i

> For more than 75 years, New England Foundry, Inc., has manufactured wood stoves for home use. In recent years, with increasing energy prices, George Mathison, president of New England Foundry, has seen sales triple. This dramatic increase in sales has ma

> Northeastern Airlines is a regional airline serving nine cities in the New England states, as well as cities in New York, New Jersey, and Pennsylvania. While nonstop flights are available for some of the routes, connecting flights are often necessary. Th

> Dr. Adinombe Watage, deputy director of the Family Planning Research Center in Nigeria’s Over-the-River Province, was assigned the task of organizing and training five teams of field workers to perform educational and outreach activitie

> What are some of the questions that can be answered with PERT and CPM?

> A linear programming problem was developed, and the feasible region was found. If the additional restriction that all variables must be integers were added to the problem, how would the size of the feasible region change? How would the optimal value of t

> Explain how to determine the number of variables and constraints in a transportation problem when only the number of sources and the number of destinations are known.

> Is the transportation model an example of decision making under certainty or decision making under uncertainty? Why?

> Explain why a process can be out of control even though all the samples fall within the upper and lower control limits.

> When using a control chart, what are some patterns that would indicate that the process is out of control?

> Explain the difference between c-charts and p-charts.

> With the company expanding into several new markets in the coming months, Cable & Moore was anticipating a large increase in sales revenue. The future looked bright for this provider of television, telephone, and Internet services. However, managemen

> Explain the difference between control charts for variables and control charts for attributes.

> What is an absorbing state? Give several examples of absorbing states.

> What is an equilibrium condition? How do we know that we have an equilibrium condition, and how can we compute equilibrium conditions given the matrix of transition probabilities?

> Describe how we can use Markov analysis to make future predictions.

> What are the vector of state probabilities and the matrix of transition probabilities, and how can they be determined?

> List the assumptions that are made in Markov analysis.

> Give two examples of random variables that would be continuous and give two examples of random variables that would be discrete.

> Why might a manager be forced to use simulation instead of an analytical model in dealing with a problem of (a). inventory ordering policy? (b). ships docking in a port to unload? (c). bank teller service windows? (d). the U.S. economy?

> The Scott Corey accounting firm is installing a new computer system. Several things must be done to make sure the system works properly before all the accounts are put into the new system. The following table provides information about this project. How

> What might cause a process to be out of control?

> Why is the central limit theorem so important in quality control?

> What is the fundamental matrix, and how is it used in determining equilibrium conditions?

> In the simulation of an order policy for drills at Simkin’s Hardware, would the results (Table 13.8) change significantly if a longer period were simulated? Why is the 10-day simulation valid or invalid? Table 13.8: ORDER QUANTITY

> Discuss the concepts of verification and validation in simulation.

> What types of management problems can be solved more easily by quantitative analysis techniques other than simulation?

> List five of the simulation software tools that are available today.

> What is operational gaming? What is systems simulation? Give examples of how each may be applied.

> Do you think the application of simulation will increase strongly in the next 10 years? Why or why not?

> Why must the service rate be greater than the arrival rate in a single-channel queuing system?

> Describe how expected activity times and variances can be computed in a PERT network.

> What is an activity? What is an event? What is an immediate predecessor?

> Why is linear programming useful in CPM crashing?

> What are deviational variables? How do they differ from decision variables in traditional LP problems?

> What is meant by satisficing, and why is the term often used in conjunction with goal programming?

> What does it mean to rank goals in goal programming? How does this affect the problem’s solution?

> List the advantages and disadvantages of solving integer programming problems by (a) rounding off and (b) enumeration.

> Explain how the maximal-flow model might be viewed as a transshipment model.

> Describe a problem that can be solved by using the shortest-route model.

> Why is a computer necessary in conducting a real world simulation?

> Andrew–Carter, Inc. (A–C), is a major Canadian producer and distributor of outdoor lighting fixtures. Its fixture is distributed throughout North America and has been in high demand for several years. The company opera

> Explain the purpose of the transshipment constraints in the linear program for a transshipment model.

> Explain what it means for an assignment model to be balanced.

> What is the waiting line problem? What are the components in a waiting line system?

> Compare the similarities and differences of linear and goal programming.

> Donna Shader, manager of the Winter Park Hotel, is considering how to restructure the front desk to reach an optimum level of staff efficiency and guest service. At present, the hotel has five clerks on duty, each with a separate waiting line, during the

> Statewide Development Corporation has built a very large apartment complex in Gainesville, Florida. As part of the student- oriented marketing strategy that has been developed, it is stated that if any problems with plumbing or air conditioning are exper

> Southwestern University (SWU), located in the small town of Stephenville, Texas, is experiencing increased interest in its football program now that a big-name coach has been hired. The increase in season ticket sales for the upcoming season means additi

> After six months of study, much political arm wrestling, and some serious financial analysis, Dr. Martin Starr, president of Southwestern University, had reached a decision. To the delight of its students and to the disappointment of its athletic booster

> Schank Marketing Research has just signed contracts to conduct studies for four clients. At present, three project managers are free for assignment to the tasks. Although all are capable of handling each assignment, the times and cost to complete the stu

> Jim Fox, an executive for Rentall Trucks, could not believe it. He had hired one of the town’s best law firms, Folley, Smith, and Christensen. Their fee for drawing up the legal contracts was over $50,000. Folley, Smith, and Christensen had omitted one i

> What are the advantages and limitations of simulation models?

> In going from Quincy to Old Bainbridge, there are 10 possible roads that George Olin can take. Each road can be considered a branch in the shortest-route problem. (a). Using the following table, determine the route from Quincy (node 1) to Old Bainbridge