Question: The following schedule was prepared by the

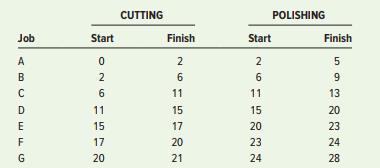

The following schedule was prepared by the production manager of Marymount Metal Shop: Determine a schedule that will result in earliest completion of all jobs on this list.

Transcribed Image Text:

CUTTING POLISHING Job Start Finish Start Finish 2 2 2 6 6 9 6 11 11 13 11 15 15 20 E 15 17 20 23 F 17 20 23 24 G 20 21 24 28 ABCD

> Formulate and then solve a linear programming model of this problem, to determine how many containers of each product to produce tomorrow to maximize profits. The company makes four juice products using orange, grapefruit, and pineapple juice. Product …

> Two operators handle adjustments for a group of 10 machines. Adjustment time is exponentially distributed and has a mean of 14 minutes per machine. The machines operate for an average of 86 minutes between adjustments. While running, each machine can tur

> A small firm makes three similar products, which all follow the same three-step process, consisting of milling, inspection, and drilling. Product A requires 12 minutes of milling, 5 minutes for inspection, and 10 minutes of drilling per unit; product B r

> For Problem 6b: a. Find the range of feasibility for each constraint, and interpret your answers. b. Determine the range of optimality for each coefficient of the objective function. Interpret your results.

> For Problem 6a, determine the following: a. The range of feasibility for each constraint b. The range of optimality for the coefficients of the objective function

> Briefly explain these terms: a. Basic variable b. Shadow price c. Range of feasibility d. Range of optimality

> For which decision environment is linear programming most suited?

> What is the maximum profit that can be achieved by purchasing additional wood?

> What general trade-offs are involved in waiting line decisions?

> If you were the manager, which option would you select? Why? Explain the disparity between the results for the two options. What assumptions did you make in your analysis? The operations manager of a soon-to-open branch of a large bank is in the process

> How has technology had an impact on analyzing waiting line systems? How has technology improved waiting line performance?

> One field representative services five customers for a computer manufacturer. Customers request assistance at an average (Poisson-distributed) rate of once every four working days. The field representative can handle an average (Poisson-distributed) of o

> What happens to the length of a waiting line in a highly variable (queuing) setting if a manager attempts to achieve a high percentage of capacity utilization?

> The manager of a regional warehouse must decide on the number of loading docks to request for a new facility in order to minimize the sum of dock costs and driver-truck costs. The manager has learned that each driver-truck combination represents a cost

> Trucks are required to pass through a weighing station so that they can be checked for weight violations. Trucks arrive at the station at the rate of 40 an hour between 7:00 p.m. and 9:00 p.m. Currently two inspectors are on duty during those hours, each

> A small town with one hospital has two ambulances to supply ambulance service. Requests for ambulances during non-holiday weekends average .45 per hour and tend to be Poisson-distributed. Travel and assistance time averages two hours per call and follows

> The following information pertains to telephone calls to a motel switchboard on a typical Tuesday a. Determine the average time callers wait to have their calls answered for each period and the probability that a caller will have to wait for each perio

> Many of a bank’s customers use its automatic teller machine to transact business after normal banking hours. During the early evening hours in the summer months, customers arrive at a certain location at the rate of one every other minute. This can be mo

> A vending machine dispenses hot chocolate or coffee. Service time is 30 seconds per cup and is constant. Customers arrive at a mean rate of 80 per hour, and this rate is Poisson-distributed. Determine the following: a. The average number of customers wai

> a. λ = 3 customers/hour μ = 5 customers/hour M = 1 (1) What is the system utilization? (2) What is the average number of customers waiting for service? (3) What is the average time customers wait in line for service? b. Repair calls are handled by one re

> During the morning hours at a catalog sales department, telephone calls come in at the rate (Poisson) of 40 per hour. Calls that cannot be answered immediately are put on hold. The system can handle eight callers on hold. If additional calls come in, the

> Son, Ltd., manufactures a variety of chemical products used by photo-processors. Son was recently bought out by a conglomerate, and managers of the two organizations have been working together to improve the efficiency of Son’s operatio

> Referring to Problem 16, suppose that each server could handle four customers per hour. Answer the questions posed in the problem. Explain why the impact of reassigning customers is much less than in Problem 16.

> The parts department of a large automobile dealership has a counter used exclusively for mechanics’ requests for parts. The time between requests can be modeled by a negative exponential distribution that has a mean of five minutes. A clerk can handle re

> One proposal is to make equal amounts of the products. What amount of each will maximize contribution, and what quantities of labor and materials will be needed? How much less will total contribution be if this proposal is adopted? Son, Ltd., manufactur

> A project manager may need two skill sets—those of a manager and those of a leader. Explain.

> This reading offers one possible reason for the existence of a long supply process. Can you think of some other possible reasons for long supply processes?

> What is the kanban aspect of JIT?

> Why is scheduling fairly simple for repetitive systems but fairly complex for job shops?

> How are scheduling and productivity related?

> What are the basic assumptions of the assignment method of linear programming?

> What are Gantt charts? How are they used in scheduling? What are the advantages of using Gantt charts?

> One approach that can be effective in reducing the impact of production bottlenecks in a job shop or batch operations setting is to use smaller lot sizes. a. What is the impact of a production bottleneck? b. Explain how small lot sizes can reduce the im

> Retail outlets that do not have an Internet presence often complain that consumers come in to “kick the tires” but then buy online from a competitor. Can you suggest some ways outlets can overcome that?

> Why are priority rules needed?

> Master Tag has not yet decided to implement this plan. List the pros and cons you think should be considered.

> Given the following information on job times and due dates, determine the optimal processing sequence using (1) FCFS, (2) SPT, (3) EDD, and (4) CR. For each method, find the average job flow time and the average job tardiness. Jobs are listed in order of

> Define each of these terms, and indicate how each is determined. a. Expected activity time. b. Variance of an activity time. c. Standard deviation of a path’s time.

> Given the information in the following table, determine the processing sequence that would result using the S/O rule. Remaining Processing Time (days) Remaining Number of Due Job Date Operations a 5 8 2 b 5 4 9 10 4 d 7 12 3 8. 10 2. 6,

> A foreman has determined processing times at a work center for a set of jobs and now wants to sequence them. Given the information shown, do the following: a. Determine the processing sequence using (1) FCFS, (2) SPT, (3) EDD, and (4) CR. For each sequen

> Given the operation times provided: a. Develop a job sequence that minimizes idle time at the two work centers. b. Construct a chart of the activities at the two centers, and determine each one’s idle time, assuming no other activities

> The times required to complete each of eight jobs in a two-machine flow shop are shown in the table that follows. Each job must follow the same sequence, beginning with machine A and moving to machine B. a. Determine a sequence that will minimize make sp

> A wholesale grocery distribution center uses a two-step process to fill orders. Tomorrow’s work will consist of filling the seven orders shown. Determine a job sequence that will minimize the time required to fill the orders. TIME

> Name three examples of unethical behavior involving scheduling and state the ethical principle each violates.

> Doctors’ and dentists’ offices frequently schedule patient visits at regularly spaced intervals. What problems can this create? Can you suggest an alternative approach to reduce these problems? Under what circumstances would regularly spaced appointments

> Businesses sometimes acquire widely dispersed processing facilities through a number of mergers or acquisitions. What trade-offs might they face in considering consolidation?

> In operations management, as in life, a balanced approach is often the best policy. One of the best examples of the benefits of this in operations management is the lean approach. Explain the basic factors that must be in place in order to achieve a bala

> What are some aspects of the project manager’s job that make it more demanding than the job of a manager working in a more routine organizational framework?

> The production manager must determine the processing sequence for seven jobs through the grinding and deburring departments. The same sequence will be followed in both departments. The manager’s goal is to move the jobs through the two

> A shoe repair operation uses a two-step sequence that all jobs in a certain category follow. All jobs can be split in half at both stations. For the group of jobs listed: a. Find the sequence that will minimize total completion time. b. Determine the amo

> What trade-offs are involved in (a) sharing information with other organizations in a supply chain and (b) the acquisition of information-processing technology?

> Briefly describe each of these priority rules: a. FCFS b. SPT c. EDD d. S/O e. Rush

> Certain Japanese have claimed that Henry Ford’s assembly line provided some of the rationale for lean. What features of assembly lines are common to lean systems?

> Name three different ways that technology has improved the ability to manage supply chains.

> Who needs to be involved in (a) decisions on technology acquisition for supply chain management and (b) supply chain management?

> A manager must make a decision on shipping. There are two shippers, A and B. Both offer a two-day rate: A for $500 and B for $525. In addition, A offers a three-day rate of $460 and a nine-dayrate of $400, and B offers a four-day rate of $450 and a seven

> Determine which shipping alternative would be most economical to ship 80 boxes of parts when each box has a price of $200 and holding costs are 30 percent of price, given this shipping information:overnight, $300, two-day, $260, six-day, $180.

> Briefly discuss vendor relations in lean systems in terms of the following issues: a. Why are they important? b. How do they tend to differ from the more adversarial relations of the past? c. Why might suppliers be hesitant about JIT purchasing?

> A manager at Strateline Manufacturing must choose between two shipping alternatives: two day freight and five-day freight. Using five-day freight would cost $135 less than using two-day freight. The primary consideration is holding cost, which is $10 per

> How did IBM achieve cost reductions by using the Internet for procurement?

> How does having a Web-based portal help IBM’s suppliers?

> To what extent has technology had an impact on lean systems?

> How does use of the Internet for procurement reduce mistakes? Indicate how using the Internet made that benefit possible.

> What are some of the potential benefits of working on a special project in one’s firm? What are some of the risks?

> What are the strategic, tactical, and operations responsibilities in supply chain management?

> What are some recent trends in supply chain management?

> Describe supplier certification and explain why it can be important.

> Discuss centralization versus decentralization in purchasing. What are the advantages of each?

> Describe how purchasing interacts with two other functional areas of an organization.

> Explain the importance of supply chain visibility.

> What are some of the main obstacles that must be overcome in converting from a traditional system to lean?

> What are some of the trade-offs that might be factors in designing a supply chain?

> Who in the organization is affected by a decision to shift from a traditional operations system to a lean system?

> Explain strategic partnering.

> What is meant by the term inventory velocity and why is this important? What is information velocity, and why is it important?

> Why might a person wish to be involved with a critical path activity? What are some of the reasons one might have for not wanting this association?

> Explain the increasing importance of the procurement function.

> What is the bullwhip effect, and why does it occur? How can it be overcome?

> Explain why each of these is critical for a successful supply chain operation: a. Integrated technology b. Information sharing c. Trust among trading partners d. Real-time information availability e. Event-response capability f. Procurement g. Risk manag

> Select three of the examples of unethical behavior in section 15.5, other than those that violate basic human rights, and indicate which principle in Table 15.2 would be violated.

> From a systems viewpoint, what are some of the environmental issues involved in a decision by a company to outsource manufacturing operations to a foreign country?

> Given the complexities and risks involved with supply chains, might it make sense for a business organization to vertically integrate and be its own supply chain?

> Some customers of Internet businesses can avoid paying state sales taxes on purchases if the Internet businesses don’t have a physical presence in their state. However, more states are enacting laws to collect taxes. What impact might this have on the cl

> What trade-offs are involved in shifting from a traditional operations system to a lean system for a manufacturing firm? For a service firm?

> A JIT system uses kanban cards to authorize movement of incoming parts. In one portion of the system, a work center uses an average of 100 parts per hour while running. The manager has assigned an inefficiency factor of .20 to the center. Standard contai

> A manager wants to determine the number of containers to use for incoming parts for a kanban system to be installed next month. The process will have a usage rate of 80 pieces per hour. Because the process is new, the manager has assigned an inefficiency

> Compute the takt time for a service system that intended to perform a standardized service. The system will have a total work time of 440 minutes per day, two 10-minute breaks, and an hour for lunch. The service system must process 90 jobs a day.

> Give three examples of unethical behavior involving lean operations, and state the relevant ethical principle that would be violated.

> What cycle time would match capacity and demand if demand is 120 units a day, there are two shifts of 480 minutes each, and workers are given three half-hour breaks during each shift, one of which is for lunch or dinner?

> Why might a probabilistic estimate of a project’s completion time based solely on the variance of the critical path be misleading? Under what circumstances would it be acceptable?

> Compute the takt time for a system where the total time per shift is 480 minutes, there is one shift, and workers are given two 15-minute breaks and 45 minutes for lunch. Daily demand is 300 units.

> Determine the number of cycles per day and a production quantity per cycle for this set of products that achieves fairly level production: Product Daily …………………Quantity F ……………………………………………...9 G ……………………………………………...8 H ………………………………………………5 K ………………………………

> Given this set of daily service operations, and assuming a processing order of A-B-C-D-E: a. Give one reason that each arrangement might be preferred over the other. b. Determine the number of repetitions for each service if four cycles are used. c. Dete

> Determine the number of cycles per day and the production quantity per cycle for this set of vehicles: Product ……………………….Daily Quantity A …………………………………………………..21 B ………………………………………………….12 C …………………………………………………..3 D ………………………………………………….15 Use the sequenc

> A machine cell uses 200 pounds of a certain material each day. Material is transported in vats that hold 20 pounds each. Cycle time for the vats is about two hours. The manager has assigned an inefficiency factor of .08 to the cell. The plant operates on

> Describe the philosophy that underlies JIT (i.e., what is JIT intended to accomplish?).

> Name and explain briefly two ways that technology has had an impact on project management.

> Reconsider the network diagram of Problem 1a. Suppose that after 12 weeks, activities 1-2, 1-3, and 2-4 have been finished; activity 2-5 is 75 percent finished; and activity 3-6 is half finished. How many weeks after the original start time should the pr

> For each of the problems listed, determine the following quantities for each activity: the earliest start time, latest start time, earliest finish time, latest finish time, and slack time. List the critical activities, and determine the expected duration

> a. Develop a list of activities and their immediate predecessors similar to the lists in this problem for this diagram: b. Construct an activity-on-arrow precedence diagram for each of the following cases. Note that each case requires the use of a dumm