Question: Toshihiro Nakamura, manufacturing engineering

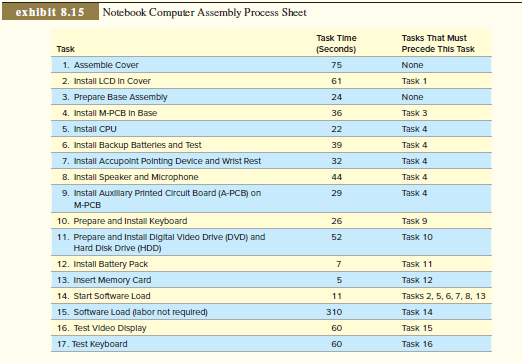

Toshihiro Nakamura, manufacturing engineering section manager, is examining the prototype assembly process sheet (shown in Exhibit 8.15) for the newest subnotebook computer model. With every new model introduced, management felt that the assembly line had to increase productivity and lower costs, usually resulting in changes to the assembly process. When a new model is designed, considerable attention is directed toward reducing the number of components and simplifying parts production and assembly requirements. This new computer was a marvel of high-tech, low-cost innovation and should give Toshiba an advantage during the upcoming fall/winter selling season. Production of the subnotebook is scheduled to begin in 10 days. Initial production for the new model is to be150 units per day, increasing to 250 units per day the following week (management thought that eventually production would reach 300 units per day). Assembly lines at the plant normally are staffed by 10 operators who work at a 14.4-meter-long assembly line. The line is organized in a straight line with workers shoulder to shoulder on one side. The line can accommodate up to 12 operators if there is a need. The line normally operates for 7.5 hours a day (employees work from 8:15 A.M. to 5:00 P.M. and regular hours includes one hour of unpaid lunch and 15 minutes of scheduled breaks). It is possible to run one, two, or three hours of overtime, but employees need at least three days’ notice for planning purposes.

The Assembly Line

At the head of the assembly line, a computer displays the daily production schedule, consisting of a list of model types and corresponding lot sizes scheduled to be assembled on the line. The models are simple variations of hard disk size, memory, and battery power. A typical production schedule includes seven or eight model types in lot sizes varying from 10 to 100 units. The models are assembled sequentially: All the units of the first model are assembled, followed by all the units of the second, and so on. This computer screen also indicates how far along the assembly line is in completing its daily schedule, which serves as a guide for the material handlers who supply parts to the assembly lines. The daily schedules are shared with the nearby Fujihashi Parts Collection and Distribution Center. Parts are brought from Fujihashi to the plant within two hours of when they are needed. The material supply system is very tightly coordinated and works well.

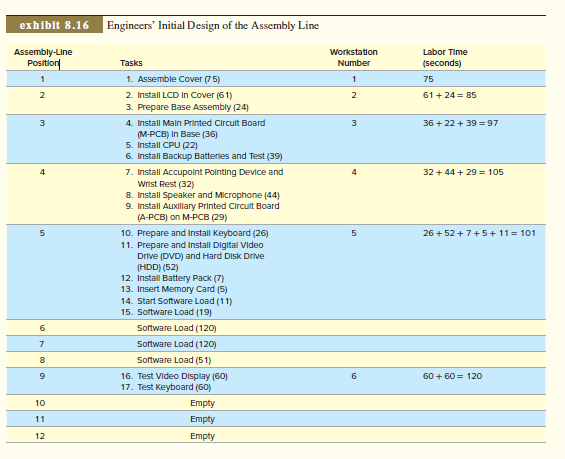

The assembly line consists of a 14.4-meter conveyor belt that carries the computers, separated at 1.2- meter intervals by white stripes on the belt. Workers stand shoulder to shoulder on one side of the conveyor and work on the units as they move by. In addition to the assembly workers, a highly skilled worker, called a “supporter,†is assigned to each line. The supporter moves along the line, assisting workers who are falling behind and replacing workers who need to take a break. Supporters also make decisions about what to do when problems are encountered during the assembly process (such as a defective part). The line speed and the number of workers vary from day to day, depending on production demand and the workers’ skills and availability. Although the assembly line has 12 positions, often they are not all used. Exhibit 8.16 provides details of how the engineers who designed the new subnotebook computer felt that the new line should be organized. These engineers designed the line assuming that one notebook would be assembled every two minutes by six line workers. The following is a brief description of what is done at each workstation: Workstation 1: The first operator lays out the major components of a computer between two white lines on the conveyor. The operator then prepares the cover for accepting the LCD screen by installing fasteners and securing a cable. Workstation 2: The second operator performs two different tasks. First, the LCD screen is installed in the cover. This task needs to be done after the cover is assembled (task 1). A second independent task done by the operator is the preparation of the base so that the main printed circuit board (M-PCB) can be installed. Workstation 3: Here the M-PCB is installed in the base. After this is done, the central processing unit (CPU) and backup batteries are installed and tested. Workstation 4: The Accupoint Pointing Device (touch pad) and wrist rest are installed, the speaker and

microphone installed, and the auxiliary printed circuit board (A-PCB) installed. These are all independent tasks that can be done after the M-PCB is installed. Workstation 5: Here tasks are performed in a sequence. First, the keyboard is installed, followed by the DVD and hard disk drive (HDD). The battery pack is then installed, followed by the memory card. The computer is then powered up and a program started that loads software that can be used to test the computer. Actually loading the software takes 310 seconds, and this is done while the computer travels through positions 6, 7, and 8 on the assembly line. Computers that do not work are sent to a rework area where they are fixed. Only about 1 percent of the computers fail to start, and these are usually quickly repaired by the supporter. Workstation 6: The video display and keyboard are tested in this workstation. After assembly, the computers are moved to a separate burn-in area that is separate from the assembly line. Here, computers are put in racks for a 24-hour, 25°C “burn-in†of the circuit components. After burn-in, the computer is tested again, software is installed, and the finished notebook computer is packaged and placed on pallets for shipment to Toshiba distribution centers around the world. Tweaking the Initial Assembly-Line Design From past experience, Toshihiro has found that the initial assembly-line design supplied by the engineers often needs to be tweaked. Consider the following questions that Toshihiro is considering:

1. What is the daily capacity of the assembly-line designed by the engineers? Assume that the assembly line has a computer at every position when it is started at the beginning of the day.

2. The line designed by the engineers is running at maximum capacity. What is the efficiency of the line relative to its use of labor? Assume that the supporter is not included in efficiency calculations.

3. How should the line be redesigned to operate at the initial 250 units per day target, assuming that no overtime will be used? What is the efficiency of your new design relative to its use of labor?

4. What about running the line at 300 units per day? If overtime were used with the engineers’ initial design, how much time would the line need to be run each day?

5. Design an assembly line that can produce 300 units per day without using overtime (specify the tasks at each position in the line as done in Exhibit 8.16)?

6. What other issues might Toshihiro consider when bringing the new assembly line up to speed?

Transcribed Image Text:

exhibit 8.15 Notebook Computer Assembly Process Sheet Task Time Tasks That Must Task (Seconds) Precede This Task 1. Assemble Cover 75 None 2. Install LCD In Cover 61 Task 1 3. Prepare Base Assembly 4. Install M-PCB In Base 24 None 36 Task 3 5. Install CPU 22 Task 4 6. Install Backup Batterles and Test 39 Task 4 7. Install Accupoint Pointing Device and Wrist Rest 8. Install Speaker and Microphone 9. Install Auxlary Printed Circult Board (A-PCB) on 32 Task 4 44 Task 4 29 Task 4 M-PCB 10. Prepare and Install Keyboard 26 Task 9 11. Prepare and Install Digital Video Drive (DVD) and Hard Disk Drive (HDD) 52 Task 10 12. Install Battery Pack 7 Task 11 13. Insert Memory Card 5 Task 12 14. Start Software Load 11 Tasks 2, 5, 6, 7, 8, 13 15. Software Load (labor not required) 16. Test Video Display 310 Task 14 60 Task 15 17. Test Keyboard 60 Task 16 exhibit 8.16 Engineers' Initial Design of the ASsembly Line Assembly-Line Workstation Labor Time Position (seconds) Tasks Number 1. Assemble Cover (7 5) 75 2. Install LCD In Cover (6 1) 3. Prepare Base Assembly (24) 2 2 61 + 24 = B5 3 4. Install Main Printed Circult Board 36+ 22 + 39 = 97 (M-PCB) In Base (36) 5. Install CPU (22) 6. Install Backup Batterles and Test (39) 7. Install Accupolnt Pointing Device and 4 4. 32 +44 + 29 = 105 Wrist Rest (32) 8. Install Speaker and Microphone (44) 9. Install Auxlary Printed Circult Board (A-PCB) on M-PCB (29) 10. Prepare and Install Keyboard (26) 11. Prepare and Install Digital Video Drive (DVD) and Hard Disk Drive (HDD) (52) 12. Install Battery Pack (7) 13. Insert Memory Card (5) 14. Start Software Load (11) 15. Software Load (19) 26+ 52 +7+5+ 11= 101 Software Load (120) 7 Software Load (120) Software Load (51) 16. Test Video Display (60) 6 60 + 60 = 120 17. Test Keyboard (60) 10 Empty 11 Empty 12 Empty

> The Dorton University president has asked the OSCM department to assign eight biology professors (A, B, C, D, E, F, G, and H) to eight offices (numbered 1 to 8 in the diagram) in the new biology building. The following distances and two-way flows are g

> Sony Electronics produces a wide variety of electronic products for the consumer marketplace, like laptop computers, PlayStation game consoles and tablet computers. What type of products would these be considered in Lee’s Uncertainty Framework?

> What type of plant tour is designed to determine the “leanness” of a plant in just 30 minutes?

> A manufacturing shop is designed to operate most efficiently at an output of 550 units per day. In the past month the plant produced 490 units. What was their capacity utilization rate last month?

> AlwaysRain Irrigation, Inc., would like to determine capacity requirements for the next four years. Currently two production lines are in place for making bronze and plastic sprinklers. Three types of sprinklers are available in both bronze and plastic:

> What type of chart compares the current project schedule with the original baseline schedule so that deviations from the original plan can be easily noticed?

> As a manager, which learning percentage would you prefer (other things being equal), 110 percent or 60 percent? Explain.

> List some occupations or sporting events where the ending is a dominant element in evaluating success.

> Sometimes a company may need to purchase goods or services that are unique, very complex, and/or extremely expensive. These would not be routine purchases, but there may be a number of vendors that could supply what is needed. What process would be use

> Measures of product development success can be organized in what three categories?

> What term refers to the development and management of supplier relationships to acquire goods and services in a way that helps achieve the immediate needs of a business?

> Which category of lifetime product costs is sometimes overemphasized, leading to a failure to fully recognize the total cost of ownership?

> What three main categories of costs are considered in figuring total cost of ownership?

> What term refers to the way some companies focus on what they do best and outsource other functions to key partners?

> Many bottled water manufacturers have recently worked with their suppliers to switch over to bottles using much less plastic than before, reducing the amount of plastic that needs to be transported, recycled, and/or disposed of. What sourcing practice i

> What is the term used for a company moving management of the complete cycle of material flow to an outside provider?

> “Project control should always focus on the critical path.” Comment.

> Two of the efficiency ratios mentioned in the chapter are the receivable turnover ratio and the inventory turnover ratio. While they are two completely separate measures, they are very similar in one way. What is the common thread between these two?

> W. W. Grainger, Inc., is a leading supplier of maintenance, repair, and operating (MRO) products to businesses and institutions in the United States, Canada, and Mexico, with an expanding presence in Japan, India, China, and Panama. The company works wit

> What are the three primary data sources used by the MRP system?

> What motivations typically cause firms to initiate a facilities location or relocation project?

> A firm uses a serial assembly system and needs answers to the following: a. An output of 900 units per shift (7.5 hours) is desired for a new processing system. The system requires product to pass through four stations where the work content at each stat

> A study-aid desk staffed by a graduate student has been established to answer students’ questions and help in working problems in your OSCM course. The desk is staffed eight hours per day. The dean wants to know how the facility is working. Statistics sh

> What kind of layout is used in a physical fitness center?

> Here is a CPM network with activity times in weeks: a. Determine the critical path. b. How many weeks will the project take to complete? c. Suppose F could be shortened by two weeks and B by one week. How would this affect the completion date? (B(5

> An office employs several clerks who create documents and has one operator who enters the document information in a computer system. The group creates documents at a rate of 25 per hour. The operator can enter the information with an average exponentiall

> Customers enter the camera department of a store at the average rate of six per hour. The department is staffed by one employee, who takes an average of six minutes to serve each arrival. Assume this is a simple Poisson arrival, exponentially distributed

> Dave’s Auto Supply custom mixes paint for its customers. The shop performs a weekly inventory count of the main colors used for mixing paint. Determine the amount of white paint that should be ordered using the following information:

> Benny the Barber owns a one-chair shop. At barber college, they told Benny that his customers would exhibit a Poisson arrival distribution and that he would provide an exponential service distribution. His market survey data indicate that customers arriv

> A graphics reproduction firm has four units of equipment that are automatic but occasionally become inoperative because of the need for supplies, maintenance, or repair. Each unit requires service roughly twice each hour, or, more precisely, each unit of

> L Winston Martin (an allergist) has an excellent system for handling his regular patients who come in just for allergy injections. Patients arrive for an injection and fill out a name slip, which is then placed in an open slot that passes into another ro

> What it the major cost trade-off that must be made in managing waiting line situations?

> How much time on average would a server need to spend on a customer to achieve a service rate of 20 customers per hour?

> If the average time between customer arrivals is 8 minutes, what is the hourly arrival rate?

> Rent’R Cars is a multisite car rental company in the city. It is trying out a new “return the car to the location most convenient for you” policy to improve customer service. But this means that the c

> The exponential distribution is often used to model what in a queuing system?

> A local fast-food restaurant wants to analyze its drive-thru window. At this time, the only information known is the average number of customers in the system (4.00) and the average time a customer spends at the restaurant (1.176 minutes). What are the a

> What is the essential requirement for mixed-model lines to be practical?

> A toll tunnel has decided to experiment with the use of a debit card for the collection of tolls. Initially, only one lane will be used. Cars are estimated to arrive at this experimental lane at the rate of 750 per hour. It will take exactly four seconds

> A local service station is open 7 days per week, 365 days per year. Sales of 10W40 grade premium oil average 20 cans per day. Inventory holding costs are $0.50 per can per year. Ordering costs are $10 per order. Lead time is two weeks. Backorders are not

> A construction project is broken down into the following 10 activities: a. Draw the network diagram. b. Find the critical path. c. If activities 1 and 10 cannot be shortened, but activities 2 and 9 can be shortened to a minimum of one week each at a cos

> Bobby, another enterprising barber, is thinking about advertising in the local newspaper because he is idle 45 percent of the time. Currently, customers arrive, on average, every 40 minutes. What does the arrival rate need to be for Bobby to be busy 85 p

> What is the objective of assembly-line balancing? How would you deal with the situation where one worker, although trying hard, is 20 percent slower than the other 10 people on a line?

> Demand for an item is 1,000 units per year. Each order placed costs $10; the annual cost to carry items in inventory is $2 each. In what quantities should the item be ordered?

> To support National Heart Week, the Heart Association plans to install a free blood pressure testing booth in El Con Mall for the week. Previous experience indicates that, on average, 10 persons per hour request a test. Assume arrivals are Poisson distri

> Burrito King (a new fast-food franchise opening up nationwide) has successfully automated burrito production for its drive-up fast-food establishments. The Burro-Master 9000 requires a constant 45 seconds to produce a batch of burritos. It has been estim

> What is the most commonly used priority rule for setting queue discipline, likely because it is seen as most fair?

> What is the term used for the situation where a potential customer arrives at a service operation and upon seeing a long line decides to leave?

> Bindley Corporation has a one-year contract to supply motors for all washing machines produced by Rinso Ltd. Rinso manufactures the washers at four locations around the country: New York, Fort Worth, San Diego, and Minneapolis. Plans call for the followi

> The customer order decoupling point determines the position of what in the supply chain?

> What is the first of the three simple steps in the high-level view of manufacturing?

> UA Hamburger Hamlet (UAHH) places a daily order for its high-volume items (hamburger patties, buns, milk, and so on). UAHH counts its current inventory on-hand once per day and phones in its order for delivery 24 hours later. Determine the number of hamb

> The following diagram represents a process where two components are made at stations A1 and A2 (one component is made at A1 and the other at A2). These components are then assembled at station B and moved through the rest of the process, where some addit

> This exercise is designed to support a plant tour event conducted as part of a class. This questionnaire is focused on assessing the “leanness” of a manufacturing plant. It might be useful to review the material on &a

> AudioCables, Inc., is currently manufacturing an adapter that has a variable cost of $.50 per unit and a selling price of $1.00 per unit. Fixed costs are $14,000. Current sales volume is 30,000 units. The firm can substantially improve the product qualit

> Owen Conner works part-time packaging software for a local distribution company in Indiana. The annual fixed cost is $10,000 for this process, direct labor is $3.50 per package, and material is $4.50 per package. The selling price will be $12.50 per pack

> Aldo Redondo drives his own car on company business. His employer reimburses him for such travel at the rate of 36 cents per mile. Aldo estimates that his fixed costs per year—such as taxes, insurance, and depreciation—are $2,052. The direct or variable

> Define, in a practical sense, what is meant by an exponential service time.

> A manufacturing process has a fixed cost of $150,000 per month. Each unit of product being produced contains $25 worth of material and takes $45 of labor. How many units are needed to break even if each completed unit has a value of $90?

> What’s the relationship between the design of a manufacturing process and the firm’s strategic competitive dimensions?

> What feature in project management information systems can be used to resolve overallocation of project resources?

> What does the product-process matrix tell us? How should the kitchen of a Chinese restaurant be structured?

> What is a customer order decoupling point? Why is it important?

> It is your responsibility, as the new head of the automotive section of Nichols Department Store, to ensure that reorder quantities for the various items have been correctly established. You decide to test one item and choose Michelin tires, XW size 185

> Check out the web sites of the consulting companies listed in the chapter outlines. Which ones impressed you most as a potential client and as a potential employee?

> What two basic questions must be answered by an inventory-control decision rule?

> What was the most complex project that you have been involved in? Give examples of the following as they pertain to the project: the work breakdown structure, tasks, subtasks, and work package. Were you on the critical path? Did it have a good project

> What is meant by a process? Describe its important features.

> Why is it that reducing moves, delays, and storages in a manufacturing process is a good thing? Can they be completed eliminated?

> What is meant by manufacturing process flow?

> How does the production volume affect break-even analysis?

> It has been noted that during World War II Germany made a critical mistake by having its formidable Tiger tanks produced by locomotive manufacturers, while American car manufacturers produced the less formidable U.S. Sherman tank. Use the product-proces

> In what way might the first-come, first-served rule be unfair to the customer waiting for service in a bank or hospital?

> Lambda Computer Products competed for and won a contract to produce two prototype units of a new type of computer that is based on laser optics rather than on electronic binary bits. The first unit produced by Lambda took 5,000 hours to produce and requi

> Logistics Consultants Inc. (LCI) provides various logistics analysis services to other firms, including facility location decisions. They have just completed a project for a major customer, but on the eve of their presentation they discovered a computer

> Have you driven any car lately? Try not to think of the insurance claims settlement process while you drive! How would you reengineer your insurance company’s claims process?

> Johnson Industries received a contract to develop and produce four high-intensity long distance receiver/transmitters for cellular telephones. The first took 2,000 labor hours and $39,000 worth of purchased and manufactured parts; the second took 1,500 l

> Management may choose to build up capacity in anticipation of demand or in response to developing demand. Cite the advantages and disadvantages of both approaches.

> Lazer Technologies Inc. (LTI) has produced a total of 20 high-power laser systems that could be used to destroy any approaching enemy missiles or aircraft. The 20 units have been produced, funded in part as private research within the research and develo

> You’ve just completed a pilot run of 10 units of a major product and found the processing time for each unit was as follows: Unit Number Time (hours) 1 ………………………………………………. 970 2 ………………………………………………. 640 3 …………………

> United Research Associates (URA) had received a contract to produce two units of a new cruise missile guidance control. The first unit took 4,000 hours to complete and cost $30,000 in materials and equipment usage. The second took 3,200 hours and cost $2

> Discuss the graphic presentations in Exhibit 4.11. Are there any other graphic outputs you would like to see if you were project manager? | Sample of Graphic Project Reports exhibit 4.11 A.Gantt Chart for Single Activities B. Total Program Cost Bre

> Honda Motor Company has discovered a problem in the exhaust system of one of its automobile lines and has voluntarily agreed to make the necessary modifications to conform with government safety requirements. Standard procedure is for t

> Omega Technology is starting production of a new supercomputer for use in large research universities. They have just completed the first unit, which took 120 man-hours to produce. Based on their experience, they estimate their learning percentage to b

> Company Z is just starting to make a brand new product they have made before. They have completed two units so far. The first unit took 12 hours to complete and the next unit took 11 hours. Based only on this information, what would be the estimate of

> Firm A typically sees a learning percentage of 85% in their processes. Firm B has a learning percentage of 80%. Which firm has the faster learning rate?

> Think about the registration process at your university. Develop a flow chart to understand it. How would you radically redesign this process?

> Distinguish between known mathematical distributions and empirical distributions.What information is needed to simulate using a known mathematical distribution?

> Santa Cruz Bottling is a manufacturer of organic soft drinks on the coast of central California. Its products are enjoying a growing reputation and increased demand throughout the American Southwest. Because of the high cost of transporting soft drinks,

> A distributor of large appliances needs to determine the order quantities and reorder points for the various products it carries. The following data refer to a specific refrigerator in its product line. Consider an even daily demand and a 365-day year.

> How do you determine the idle-time percentage from a given assembly-line balance?

> A company has just tested the skills of two applicants for the same job. They found that applicant A had a higher learning rate than applicant B. Should they definitely higher applicant A?

> True or False: The only learning for an organization comes from the individual learning of its employees.

> The purpose of value analysis/value engineering is to _____________

> The first step in developing a house of quality is to develop a list of __________________.

> Designing products for aesthetics and with the user in mind is generally called what?

> A process that emphasizes cross-functional integration and concurrent development of a product and its associated processes is known as _________________________.

> In discussing characteristics of efficient plants, Goodson, developer of “Rapid Plant Assessments”, suggests that numerous forklifts are a sign of poor space utilization. What do you think is behind this observation?

> Match the following product types to the appropriate product development description. Technology-push A. Entail unusually large uncertainties about the technology or market. The development process takes steps to address those uncertainties. produc

> The following chart is a partial house of quality for a golf country club. Provide an importance weighting from your perspective (or that of a golfing friend) in the unshaded areas. If you can, using the QFD approach, compare it to a club where you or yo