Question: As we discussed at the beginning of

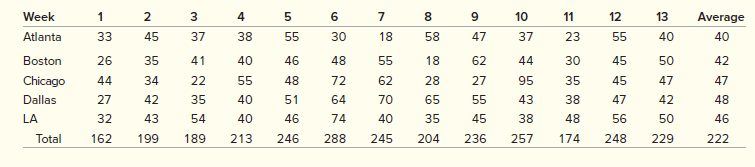

As we discussed at the beginning of the chapter, Starbucks has a large, global supply chain that must efficiently supply over 17,000 stores. Although the stores might appear to be very similar, they are actually very different. Depending on the location of the store, its size, and the profile of the customers served, Starbucks management configures the store offerings to take maximum advantage of the space available and customer preferences. Starbucks’ actual distribution system is much more complex, but for the purpose of our exercise let’s focus on a single item that is currently distributed through five distribution centers in the United States. Our item is a logo-branded coffeemaker that is sold at some of the larger retail stores. The coffeemaker has been a steady seller over the years due to its reliability and rugged construction. Starbucks does not consider this a seasonal product, but there is some variability in demand. Demand for the product over the past 13 weeks is shown in the following table. The demand at the distribution centers (DCs) varies between about 40 units, on average, per week in Atlanta and 48 units in Dallas. The current quarter’s data are pretty close to the demand shown in the table. Management would like you to experiment with some forecasting models to determine what should be used in a new system to be implemented. The new system is programmed to use one of two forecasting models: simple moving average or exponential smoothing.

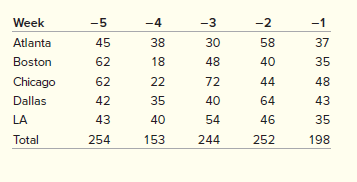

1. Consider using a simple moving average model. Experiment with models using five weeks’ and three weeks’ past data. The past data in each region are given as follows (week −1 is the week before week 1 in the table, −2 is two weeks before week 1, etc.). Evaluate the forecasts that would have been made over the 13 weeks using the overall (at the end of the 13 weeks) mean absolute deviation, mean absolute percent error, and tracking signal as criteria.

2. Next, consider using a simple exponential smoothing model. In your analysis, test two alpha values, 0.2 and 0.4. Use the same criteria for evaluating the model as in part 1. When using an alpha value of 0.2, assume that the forecast for week 1 is the past three-week average (the average demand for periods −3, −2, and −1). For the model using an alpha of 0.4, assume that the forecast for week 1 is the past five-week average.

3. Starbucks is considering simplifying the supply chain for their coffeemaker. Instead of stocking the coffeemaker in all five distribution centers, they are considering only supplying it from a single location. Evaluate this option by analyzing how accurate the forecast would be based on the demand aggregated across all regions. Use the model that you think is best from your analysis of parts 1 and 2. Evaluate your new forecast using mean absolute deviation, mean absolute percent error, and the tracking signal.

4. What are the advantages and disadvantages of aggregating demand from a forecasting view? Are there other things that should be considered when going from multiple DCs to a DC?

Transcribed Image Text:

Week 1 2 4 7 8 10 11 12 13 Average Atlanta 33 45 37 38 55 30 18 58 47 37 23 55 40 40 Boston 26 35 41 40 46 48 55 18 62 44 30 45 50 42 Chicago 44 34 22 55 48 72 62 28 27 95 35 45 47 47 Dallas 27 42 35 40 51 64 70 65 55 43 38 47 42 48 LA 32 43 54 40 46 74 40 35 45 38 48 56 50 46 Total 162 199 189 213 246 288 245 204 236 257 174 248 229 222 LO Week -5 -4 -3 -2 -1 Atlanta 45 38 30 58 37 Boston 62 18 48 40 35 Chicago 62 22 72 44 48 Dallas 42 35 40 64 43 LA 43 40 54 46 35 Total 254 153 244 252 198

> The ABC Floral Shop sold the following number of geraniums during the last two weeks: Develop a spreadsheet for the following. a. Calculate forecasts using a three- and five-period moving average. b. Graph these forecasts and the original data using Exce

> Qualitative forecasting methods should be used only as a last resort. Agree or disagree? Comment.

> For the following situations, comment on whether inspection by variables or by attributes might be more appropriate: a. Filling packaged food containers to the proper weight. b. Inspecting for defects in cloth. c. Inspecting appliances for surface imperf

> Product A has an MTBF of 30 hours and an MTTR of 5 hours. Product B has an MTBF of 40 hours and an MTTR of 2 hours. a. Which product has higher reliability? b. Which product has better maintainability? c. Which product has greater availability?

> For a particular operation, the setup time is 10 minutes and the run time is 50 minutes to produce a standard lot of 40 parts. It takes three additional hours to circulate a container of parts after production is completed. The demand rate is 20,000 part

> Why did the concepts, principles, and techniques of lean emerge and evolve in Japan, not in the Western countries?

> Palin’s Muffler Shop has one standard muffler that fits a large variety of cars. The shop wishes to establish a periodic review system to manage inventory of this standard muffler. Use the information in the following table to determine

> The Stylish Hair Salon has three stylists who provide services to women. After checking in with the receptionist, which takes an average of 1 minute, the customer’s hair is washed, dried, and styled, taking an average of 25 minutes. The payment takes 3 m

> Explain Little’s Law in your own words. How can it be used, and what are its limitations?

> How do the managerial tasks differ among the services described in question 2?

> The rate of productivity improvement in the service industries has been much lower than in manufacturing. Can this be attributed to process selection decisions? What problems would be involved in using more efficient processes in service industries?

> Describe the steps that might be required in writing and producing a play. Compare these steps to the three steps for NPD described in Section 3.2. Is there a correspondence?

> An operations manager was heard complaining, “The boss never listens to me—all the boss wants from me is to avoid making waves. I rarely get any capital to improve operations.” a. Does the business have an operations strategy? b. What should be done abou

> What is the difference between operations management and supply chain management?

> How should ShelterBox respond to the issues it faces to best satisfy its stakeholders?

> Evaluate the pros and cons of the stormwater project on both financial and non-financial factors and make a recommendation on what Richard Murphy should decide.

> What is the process capability for each operator-machine combination?

> At a border inspection station, vehicles arrive at the rate of 10 per hour in a Poisson distribution. For simplicity in this problem, assume there is only one lane and one inspector, who can inspect vehicles at the rate of 12 per hour in an exponentially

> Do you agree with any of the points made by skeptics about the original Six Sigma program at 3M?

> Why is it important to align the organization’s culture with its larger goals?

> What will be the impact of these options on the MRP system currently in use?

> How can the system be improved and draw a new value stream map

> For each service failure point in question 2 is it self-service or provided by the hotel, and is it high contact or low contact service? Does this indicate any possibilities for improvement?

> Prepare a parts explosion to support the master schedule. What parts should be ordered each week? Are there enough planned orders in time to support your master schedule?

> Evaluate the current inventory management system at Southern Toro. What inventory management system would you recommend?

> Given a business strategy of being the word leader in manufacturing electric cars with innovative technology, what operations and supply chain strategy do you think BYD should pursue? Identify what operations and supply chain should do to help BYD compet

> What other factors should be considered in making this decision?

> Use the classical decomposition method to forecast average demand for 2016 by month. What is your forecast of monthly average demand for 2016?

> W. W. Grainger, Inc., is a leading supplier of maintenance, repair, and operating (MRO) products to businesses and institutions in the United States, Canada, and Mexico, with an expanding presence in Japan, India, China, and Panama. The company works wit

> A manufacturer has two shipments to make from Minneapolis to Chicago. Both shipments weigh 8500 pounds. The two shipments can be shipped separately to Chicago at a cost of $2.00 per mile for a total of 409 miles and will take one day for each shipment. T

> Why is trucking the most used mode of transportation relative to rail or water?

> A service company has the following financial information (in millions of $) Sales………………………………………………………………….. $510 Cost of outsourced facilitating goods ……………………….210 Cost of in-house services provided ………………………….199 Administrative costs …………………….………………

> Why are sourcing decisions considered to be strategic?

> Define the supply chains for the following products from the first source of raw materials to the final customer: a. Big Mac b. Gasoline c. Automobile repair d. A textbook

> Why is demand history irrelevant for the management of raw-materials and work-in-process inventories?

> A supplier has come to you and offered the following deal. If you buy 29 or fewer cases of cleaning solution, the cost will be $25 for each case. If you buy 30 or more cases, the cost will be $20 per case. Assume your cost of carrying inventory is 15 per

> The Grinell Machine Shop makes a line of metal tables. Some of these tables are carried in finished goods inventory. A particular table has the following characteristics: Sales = 300 per year Setup cost = $1200 per setup (this includes machine setup for

> Why are stockout costs difficult to determine? Suggest an approach that might be used to estimate them

> The following activities are required in starting up a new plant: a. Draw a network for this project. b. Make a forward and backward pass to determine ES, LS, EF, and LF. c. Calculate slack. d. Prepare a Gantt chart for this project. Immediate Acti

> What is the term used to refer to inventory while in distribution – i.e. being moved within the supply chain?

> The annual demand for a product is 15,600 units. The weekly demand is 300 units with a standard deviation of 90 units. The cost to place an order is $31.20, and the time from ordering to receipt is four weeks. The annual inventory carrying cost is $0.10

> Would you expect the exponential distribution to be a good approximation of service times for a. Buying an airline ticket at the airport? b. Riding a merry-go-round at a carnival? c. Checking out of a hotel? d. Completing a midterm exam in your OM class?

> Why should a manager of a bank home office be evaluated differently than a manager of a bank branch?

> The manager of a small post office is concerned that the growing township is overloading the one-window service being offered. Sample data are collected on 100 individuals who arrive for service. Using the following random number sequence, simulate six

> You are planning the new layout for the local branch of the Sixth Ninth Bank. You are considering separate cashier windows for the three different classes of service. Each class of service would be separate, with its own cashiers and customers. Oddly eno

> Palin’s Muffler Shop has one standard muffler that fits a large variety of cars. The shop wishes to establish a periodic review system to manage inventory of this standard muffler. Use the information in the following table to determine

> At a border inspection station, vehicles arrive at the rate of 10 per hour in a Poisson distribution. For simplicity in this problem, assume there is only one lane and one inspector, who can inspect vehicles at the rate of 12 per hour in an exponentially

> W. W. Grainger, Inc., is a leading supplier of maintenance, repair, and operating (MRO) products to businesses and institutions in the United States, Canada, and Mexico, with an expanding presence in Japan, India, China, and Panama. The company works wit

> What is the term used to refer to inventory while in distribution – i.e. being moved within the supply chain?

> The flow of materials through eight departments is shown as follows. Even though the table shows flows into and out of the different departments, assume that the direction of flow is not important. In addition, assume that the cost of moving material dep

> 1. Using Exhibit 1.3 as a model, describe the source-make-deliver-return relationships in the following systems: a. An airline b. An automobile manufacturer c. A hospital d. An insurance company Making Sourcing Planning Delivering Returning

> Why might it be difficult to develop a manufacturing cell?

> What are the implications for cost accounting of lean production?

> Explain the relationship between quality and productivity under the lean philosophy.

> Daily demand for a certain product is normally distributed, with a mean of 100 and a standard deviation of 15. The supplier is reliable and maintains a constant lead time of 5 days. The cost of placing an order is $10 and the cost of holding inventory is

> Consider the following financial data from the past year for Midwest Outdoor Equipment Corporation. a. Compute the receivable turnover ratio. b. Compute the inventory turnover ratio. c. Compute the asset turnover ratio. Gross Income $25,240,000 Total

> The annual demand for a product is 15,600 units. The weekly demand is 300 units with a standard deviation of 90 units. The cost to place an order is $31.20, and the time from ordering to receipt is four weeks. The annual inventory carrying cost is $0.10

> Why is lean hard to implement in practice?

> Will lean work in service environments? Why or why not?

> With so much productive capacity and room for expansion in the United States, why would a company based in the United States choose to purchase items from foreign firm? Discuss the pros and cons.

> In which ways, if any, are the following systems analogous to Kanban: returning empty bottles to the supermarket and picking up filled one; running a hot dog stand at lunchtime; withdrawing money from a checking account; raking leaves into bags?

> As the field of OSCM has advanced, new concepts have been applied to help companies compete in a number of ways, including the advertisement of the firm’s products or services. One recent concept to gain the attention of companies is promoting sustainab

> Explain how cards are used in a Kanban system.

> Discuss what is meant by forward loading and backward loading.

> What are the roles of suppliers and customers in a lean system?

> The following activities are part of a project to be scheduled using CPM: a. Draw the network. b. What is the critical path? c. How many weeks will it take to complete the project? d. How much slack does activity B have? АСTIVITY IMMEDIATE PREDECES

> What difference does it make if a customer wants a 10,000 unit order produced and delivered all at one time or in 2,500 unit batches?

> What inventory-related term is used to refer to points in a health care process where waiting takes place, either before or after treatment takes place?

> At first glance, the concepts of the focused factory and capacity flexibility may seem to contradict each other. Do they really?

> A fishing boat manufacturer, Pro Fishing Boats, is having many problems with critical globally sourced parts. Pro Fishing has two manufacturing facilities in the United States. The firm’s reliance on efficient global supply chain operations is i

> You are planning employees for a bank. You plan for six tellers. Tellers take 15 minutes per customer, with a standard deviation of seven minutes. Customers will arrive one every three minutes according to an exponential distribution (recall that the sta

> Circuit Board Fabricators, Inc. (CBF), is a small manufacturer of circuit boards located in California near San Jose. Companies such as Apple Computer and Hewlett- Packard use the company to make boards for prototypes of new products. It is important th

> Discuss how a production system is scheduled using MRP logic, JIT logic, and synchronous manufacturing logic.

> Cyprus Citrus Cooperative ships a high volume of individual orders for oranges to northern Europe. The paperwork for the shipping notices is done in the accompanying layout. Revise the layout to improve the flow and conserve space if possible. Filke

> Value stream mapping involves first developing a baseline map of the current situation of a company’s external and/or internal operations, and then applying lean concepts, developing a future state map that shows improved operations. Ex

> What type of worker constitutes the largest component of the hospital’s workforce?

> A cafeteria serving line has a coffee urn from which customers serve themselves. Arrivals at the urn follow a Poisson distribution at the rate of three per minute. In serving themselves, customers take about 15 seconds, exponentially distributed. a. How

> Do you think learning curve analysis has application in a service business like a restaurant? Why or why not?

> The Bijou Theater shows vintage movies. Customers arrive at the theater line at the rate of 100 per hour. The ticket seller averages 30 seconds per customer, which includes placing validation stamps on customers’ parking lot receipts and punching their f

> Students arrive at the Administrative Services Office at an average of one every 15 minutes, and their requests take, on average, 10 minutes to be processed. The service counter is staffed by only one clerk, Judy Gumshoes, who works eight hours per day.

> A bank of machines in a manufacturing shop breaks down according to the following interarrival time distribution. The time it takes one repairperson to complete the repair of a machine is given in the service time distribution. Simulate the breakdown o

> During the campus Spring Fling, the bumper car amusement attraction has a problem of cars becoming disabled and in need of repair. Repair personnel can be hired at the rate of $20 per hour, but they only work as one team. Thus, if one person is hired, he

> One manufacturer has seen a typical learning percentage of 90% in their firm. They have recently found out that a competitor of theirs has a percentage of 85%. What do you think about this?

> “Shouldice Hospital, the house that hernias built, is a converted country estate which gives the hospital ‘a country club’ appeal.” A quote from American Medical News Shouldice Hosp

> Why would subcontractors for a government project want their activities on the critical path? Under what conditions would they try to avoid being on the critical path?

> What factors account for the resurgence of interest in OSCM today?

> Francis Johnson’s plant needs to design an efficient assembly line to make a new product. The assembly line needs to produce 15 units per hour, and there is room for only four workstations. The tasks and the order in which they must be

> Discuss ways to use lean to improve one of the following: a pizza restaurant, a hospital, or an auto dealership.

> As Operations Manager, you are concerned about being able to meet sales requirements in the coming months. You have just been given the following production report. Find the average monthly productivity (units per machine hour). JAN FEB MAR APR Uni

> MRP is based on what type of demand?

> Various financial data for the past two years follow. Calculate the total productivity measure and the partial measures for labor, capital, and raw materials for this company for both years. What do these measures tell you about this compa

> Compare the importance and relevance of quality control in JIT, MRP, and synchronous manufacturing.

> A U.S. manufacturing company operating a subsidiary in an LDC (less-developed country) shows the following results: a. Calculate partial labor and capital productivity figures for the parent and subsidiary. Do the results seem misleading

> Sailmaster makes high-performance sails for competitive windsurfers. Below is information about the inputs and outputs for one model, the Windy 2000. Calculate the productivity in sales revenue/labor expense. Units sold 1,217 Sale price each $1,70

> What methodology is used to assess a client’s performance relative to the expectations of its customers or the performance of its competitors?

> Daily demand for a product is 60 units with a standard deviation of 10 units. The review period is 10 days, and lead time is 2 days. At the time of review, there are 100 units in stock. If 98 percent service probability is desired, how many units should

> Find examples where companies have used features related to environmental sustainability to win new customers.

> In manufacturing, quality measures are largely based on hard evidence. In health care, quality and service measures are largely based on what?

> What relationship is there between learning curves and productivity measurement?

> Why is simulation often called a technique of last resort?