Question: I can’t see why you have

I can’t see why you have to spend so much time looking at our processes. Hey, we have everything under control. It has been over five years since we got our last EPA inspection and nearly six years since we got our last major citation and fine. Things are going really smoothly and I really don’t see why you have to look at the process. Now, why don’t you go out and get me some cost savings? Every time I can save a penny per finished lighting assembly, I get that much better a chance to keep my business with the big boys.â€

With those words, Barry Jamieson, the plant manager of Midwestern Lighting’s Light Fixture Plant (LFP) dismissed Tim Bryant. Tim had been hired some six months ago to help improve overall operations at LFP. Initially, he had been brought in by corporate to identify opportunities for cost reduction and for reducing scrap and landfill-related costs. When he arrived at LFP, located in New Hudson, Michigan, Tim found a plant that was operating under a siege mentality. Everyone knew that they had to reduce costs and improve operating efficiencies if they hoped to win another contract from LFP’s three major customers. LFP was unique in that it was one of the few plants in the automotive industry that built light fixtures for GM, Ford, and Daimler-Chrysler. While LFP was noted for its superb quality, it was also recognized as not being very cost efficient. The managers of Midwestern Lighting had tried to convince the plant manager at LFP to consider QS9000 certification. That effort was a disaster and ultimately resulted in the dismissal of the plant manager. It was that dismissal that gave rise to the hiring of Barry Jamieson. Since arriving at LFP, Barry had developed a reputation for being a hard-nosed manager. To Barry, if you couldn’t reduce cost, then you didn’t have anything to say of importance. Barry was not really excited by Tim’s presence. To Barry, Tim represented nothing more than increased overhead.

The Production Process Described

Since arriving at LFP, Tim could not help but feel that there were too many “diamonds in the rough†to ignore. Typical was the process for making the taillight assemblies for the Dodge Ram, one of the best-selling trucks in the market. The process began with the back plate. This was a long black piece of extruded ABS plastic (produced in another part of the plant) that contained two concave depressions—one for the turn light and one for the backup light. These were withdrawn from a temporary storage location found near the assembly line. Each back plate was first checked for cosmetic defects. Those that failed this step were placed in a bin where they were eventually used as a source of raw material for regrinds. Any plate passing this test was placed in a metalization chamber, where nickel metal particles were sprayed on using a high-pressure water-based system. Because of the nature of the process, only half of the material ever reached the back plate. The rest either fell to the bottom of the chamber or was vented out. Periodically, the chamber had to be taken off-line and cleaned out. This process took 1 to 2 days and effectively shut down production of the taillight.

After the parts were metalized, they were removed from the chamber and checked for completeness and evenness of the coverage. Any rejected parts were placed in a bin. Because of the presence of the metal coating, the back plate could not be recycled, so it had to be landfilled. The accepted parts went into a rack where they waited for the arrival of lenses from a supplier. A plastic-wrapped film covered the lenses. Each lens, as it arrived from the sup-plier, was checked for surface flaws. Any rejected lenses were then put into a recycle bin, where they were used as inputs for any parts requiring low-grade black plastic.

The next step in the process was mating. At this stage, each lens was mated to a back plate. This was accomplished by placing the back plate and the lens into two fixtures. These fixtures were then fed into an automated gluing machine. The machine placed a bead of glue on the lens, waited for 10 seconds and then placed the lens onto the back plate. Periodically, the gluing machine had to be purged and cleaned. This was typically done twice a shift; each instance required 30 minutes. This process was fairly messy and required several globs of glue to be expressed through the nozzle. After this was done, the last glob of glue was then expressed and the nozzle was removed. The machine had four nozzles. The residual glue and nozzles were then thrown into an old 55-gallon barrel. Because this barrel was used as a receptacle for all sorts of scrap (including floor sweepings and cigarette butts), the only disposal option was a landfill.

After mating, the back light assembly was next tested for leaks. Placing the body into a tank of water and then shooting a burst of air through it completed the testing. Again, any assemblies that failed this test were put into a bin for eventual disposal in a landfill site. Those that passed this stage next proceeded to the finishing assembly. It was here that two lightbulb assemblies were first made. These assemblies required one receiver and one lightbulb each.

Both the receiver and the lightbulbs were provided by out-side suppliers. After they were assembled, the assemblies were inserted into the appropriate holes in the car body. The light assembly was then inspected for performance and surface blemishes. Any problem assemblies were put aside for rework. Those that could not be reworked were set aside for disposal (again landfilled). The remaining “good†assemblies were packed into a cardboard box and shipped out to the Dodge Ram assembly plant.

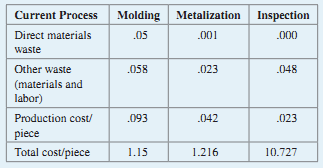

The current practice at LFP was to allocate the total production cost to the number of good assemblies produced. By working with the material requirements planning system at LFP, Tim and others were able to track the following costs associated with waste in the process. For the tail-light assemblies, the line produced 3,600 per shift. Labor and overhead costs were considered to be fixed.

Required:

1. Assess the production process for the Dodge Ram tail-light assembly. How efficient is it?

2. Develop a process map for this operation.

3. Where are the largest opportunities to reduce waste and associated costs?

4. What strategy/approach would you use for making recommendations to Barry Jamieson?

> Six Sigma quality (3.4 defects per million units produced) is probably a bit much to ask of Rachel’s old oven (see problem 2). a. What would the standard deviation in the temperature of her oven need to be if she settled for a “Three Sigma” level of qual

> Rachel loves to bake cookies, but she has an old oven that has trouble maintaining a constant temperature. If the acceptable temperature range for making the cookies is 350 plus or minus 5 degrees, what is the allowable standard deviation in the temperat

> I visited my old pal Dinsmore recently. He had called to let me know that he had taken over as general manager of the Flagship hotel about six months ago, and he thought that I might be interested in seeing a real hotel from the inside. He also indicated

> Roberta Brown sat at her desk and looked through the preliminary slide deck she had prepared. This presentation had to be good. In two weeks she would be giving the presentation to the top management team of Aqua-Fun. The goal: to secure their commitment

> Things were not going well at Bully Boy Products (BBP). BBP was a regional producer of organic fertilizer, potting soil, growing loam, and various gardening products for the discriminating gardener. It had been founded in 1976 when two agriculture studen

> Late on the evening of Sunday, April 14, 1912, RMS Titanic, while on her maiden voyage, struck an iceberg about two days from New York City. Within three hours, she was gone (Monday, April 15, 1912). On this voyage, there were 2,201 passengers and crew m

> Pick a product good or service that you are interested in consuming sometime in the near future. Analyze the offerings of two competing firms. How do the products compare on various dimensions of quality? From these differences, what can you infer about

> The chapter noted that digital technologies are giving firms and their consumers increased visibility into the supply chain and its activities. Would this visibility be important to you? Why? Would you be willing to change your shopping habits in respons

> It has been said that quality management is really a “people” system, more than a technical system. If this is true, what conditions must first be in place for a firm to be successful with quality management? What are the possible repercussions for the f

> A critical concept introduced in this chapter was that of the value proposition. Explore two competing products (e.g., RIM’s Blackberry and Apple’s IPhone). Identify the underlying value propositions present in these products and how this proposition is

> You have been appointed head of quality control for your organization (a firm you have worked at or your college). During the first month, you interview disciples of Deming, Juran, and Crosby. Each seems to be equally affable and competent. Which consult

> Employee empowerment is an essential element of quality management, especially in services. From your own experience, cite instances where a service provider empowered its employee to go the extra mile to delight you. Then indicate an instance where the

> When does it make economical sense to crash project activities? How do you know when to stop?

> What project factors would make you more or less comfortable with a lower probability that the project will be completed on time?

> Suppose that your project has two activity paths of about the same length, but one path is made up of more uncertain activities while the other path is fairly routine. How would you manage the activities on these two paths differently?

> Why does it never make sense to crash activities that are not on the critical path?

> Trail Frames Chassis (TFC) of Elkhart, Indiana, is a major manufacturer of chassis for the motor home and van markets. Since it was founded in 1976 by two unemployed truck-manufacturing engineers, TFC has grown into one of the major suppliers in this mar

> Cemex is one of the world’s largest providers of building materials, mainly concrete and cement (www.cemex.com) for the building of sports complexes, skyscrapers, and high-scale infra-structure (e.g., roads, bridges). The company is over 100 years old an

> Dave Eisenhart, senior editor for Mountain Publishing, Inc., looked out his window as he considered the operational implications of the changes he had just heard discussed in the company’s annual strategic planning meeting. The future looked to be both e

> As his plane landed at Port Columbus International Air- port, Adam Warren, Chief Supply Chain Officer for Sup- ply Chain Operations and Services, (SCOS), switched his phone out of airplane mode and waited for cellular service to resume and the messages h

> When can a consumer be a critical consumer? In other words, when does it make sense to focus on consumers such as retail stores, distributors, or buyers, rather than on the end consumer?

> Select two products that you have recently purchased; one should be a service and the other a manufactured good. Think about the process that you used to make the decision to purchase each item. What product characteristics were most important to you? Wh

> How do you convince the auto industry to accept and sup- port the need to develop and build a super-efficient sport utility vehicle (SUV)? At first glance, this would be a no- brainer. Everyone wants an SUV that is fuel efficient. All that is needed is a

> Lucy, I thought that you told me and the planning committee that this move to recycle storage plastics was going to save us money. But, look here. I just got the bill for last month’s disposal of our plastic. We wound up paying $3,000, rather than being

> Welcome everyone. Robert, please turn on the television.” Vice President of Global Procurement, Stefan Schrettle, started the meeting with these words. The components sourcing and procurement team had been hurriedly assembled at Schrettle’s request. Robe

> The summit meeting at Monolith Productions started promptly on August 20 at 10:45 a.m. The president of the company, Hugo Monolith III, called the meeting of his vice presidents to order. “Ladies and gentlemen, thank you for meeting here on such short no

> Derek had a busy summer ahead of him. It was February 1, and Derek was planning out a summer full of activities that included a backpacking tour of Europe, doing some work for his father, and completing an online summer course offered by his university.

> The Casual Furniture Company (CFC) makes a variety of bookshelves for homes and businesses. The shelves come in various heights, widths, materials, and finishes. Effective requirements planning is essential for CFC’s performance, and it

> Adam Rodriguez, the vice president of supply chain management for QP Industries, sat in his office, contemplating what he had to tell the executive leadership team at tomorrow’s meeting. During the last two years, lead times for transmitting orders betwe

> The following case is based on one of the coauthor’s experiences with an actual company and its management. Fiona Richey knew that she had been given the opportunity of a lifetime. She had just been hired to be an internal troubleshooter and consultant b

> Bill Smith, director of business planning for C&F Apparel, chewed on a pencil as he looked out the window of his fourth-story office. These bad forecasts are killing us, he thought. Forecast errors for the fall season’s sales had ranged from 50 to 200 pe

> Rachel Kirkpatrick thought to herself, “What a waste,” as she threw away three bags full of unsold items and spoiled ingredients. “I have to get better at estimating how much food to order and prepare

> How would you define capabilities within a school or business?

> Lear Corporation, headquartered in Southfield, Michigan, is one of the world’s 10 largest independent automotive suppliers and the leading player in the $45 billion global auto interiors market. This market consists of such items as seating systems, inte

> Elise Lovejoy, the new logistics coordinator at Spartan Plastics, was looking at the stack of papers and the two computer screens in front of her. It was Friday afternoon— the Friday before the long weekend—and she sti

> The five-year dining services contract at Midwest University, a residential campus with 20,000 students located in Ohio, is expiring in three months. The supplier must be able to perform all aspects of dining services operations including menu planning,

> Trail Frames Chassis (TFC) of Elkhart, Indiana, is a major manufacturer of chassis for the motor home and van markets. Two unemployed truck-manufacturing engineers founded TFC in 1976. Since then, the company has grown into one of the largest suppliers o

> Karen Williams, the new director of supply management at Best Banks, was excited to be working at her new job. After gaining over 10 years of experience in various supply management positions at a first-tier automotive supplier, she was looking forward t

> Harry Chamberlain, vice president of Tiler Industries, closed the phone call by saying, “Well thanks, Jim. We appreciate the call even though it was bad news. We’re sorry we didn’t get the contract for the SRW installation from Phoenix, but we understand

> It was a tough year for Western Telephone Manufacturing (WTM) of Canton, Michigan. Until this year, WTM had been the darling of Wall Street. This company had become one of the first to wholly embrace the concepts of Six Sigma and Total Quality Management

> Jane Polski, the newly hired director of university purchasing, took one final look at the report from her purchasing manager, removed her glasses, and rubbed the bridge of her nose. Surely, she thought, things could not be that bad. According to the rep

> Good Guy Hospital Supply (GGHS) was founded in the 1960s to serve the hospital and nursing home industry. Since then, its sales have grown an average of 26 percent per year, through both geographical expansion and increased existing-market penetration. K

> Dexter pored over the table of data he had compiled using inputs from purchasing, internal inventory managers, accounting, and Disco (Dexter’s Chicken’s purchasing co-op and sole distributor). He hoped that he had enough information to make a well-founde

> Apply the corporate/SBU/functional planning hierarchy introduced in this chapter to your university/college or business. What would be the equivalent to corporate planning? SBU planning? Functional Planning?

> Tasty Treats is a distributor of candy and snack products serving customers in a six-state region of the Midwest ern United States. Bill Jones, chief operations officer, has been concerned about inventory levels and inventory performance at Tasty Treats

> Champion Electric, a regional supplier of electrical and electronic components, keeps thousands of SKUs (stock keeping units) of various products on hand for its customers. A new operations manager, Barb Patterson, has just been hired to replace Bob, who

> As he stopped to refill his coffee mug, Roger Terry began to recall some of the comments he had heard from various members of the single-block product development team (see the comments reproduced below). The following comments were gathered from informa

> The ALPHA single-block timer development project had not gone exactly as planned. The product development time-to-market was 48 months instead of the planned 30 months, and capital expenditures for the project were at least 30 percent over budget. On the

> Roger Terry hurried down the hallway toward the planning meeting for the ALPHA timer product development project. Terry had served as project manager for the initial stage of the ALPHA single-block product development, and he was now preparing to start t

> To: Brad Hadley, President, American Vinyl Products (AVP) From: Bev Trudeau, Director of Purchasing, American Performance Car, CA Subject: Customer Service at American Vinyl Products Our two companies have basically had a good relationship ov

> You are the purchasing director for Midas Gold Juice Company, a small Midwestern fruit-juice company that produces a line of premium, limited-run fruit juice (Slogan: Midas Juice—you’ll be touched by the Gold). As one of your responsibilities, you review

> The top managers of Evergreen Products of East Lansing, MI, have asked you to act as a consultant on a problem plaguing the entire company. Evergreen Products manufactures decorated containers and care tags for a market consisting primarily of small- to

> Steinway pianos have long been the premier brand among serious pianists. Franz Liszt called his Steinway “a glorious masterpiece.” Gioacchino Rossini, a 19th-century com-poser, described the Steinway sound as “great as thunder, sweet as the fluting of a

> Why should the firm never outsource its core capabilities? What happens if the firm is approached by a supplier who is willing to supply goods and services based on these core capabilities at a significantly lower price? What should the firm do?

> Otis Toy Trains of Minneapolis, Minnesota, was a land-mark company in the toy business. Since the 1900s, it had been responsible for building electrical and steam-driven toy trains. Since the 1950s, Otis trains had developed a major presence on children’

> It was late on Friday, and Lisa Jacobs, the CEO of Lil’ Me Dolls, re-read the document before her. It was a proposal from the MOT (Millions of Toys) retail toy chain offering to carry the Lil’ Me line of dolls. At first glance, this seemed to be too good

> The American South and the American Midwest experience natural disasters on a regular basis (hurricanes such Hurricane Katrina in the American South and tornados in the American Midwest). Whenever such a disaster takes place, organizations such as the Am

> One common approach that companies use to protect human rights is a supplier code of conduct. How can you increase the effectiveness of a code of conduct?

> The Triple Bottom Line can be viewed as a three-legged stool in that each element must be present or, if one or more elements are removed, then the entire structure collapses. To what extent do you agree with this approach? Why is it important that each

> Why is it that some managers are not willing to pursue more aggressively environmental sustainability even when presented with compelling reasons for its need? (HINT: think about issues such level of resources available, risk of failure, and how the mana

> What are some operations/supply chain management strategies that can be used to deal with the challenges of diminishing natural resources?

> In a recent study by MIT, it was found that the Toyota Prius, a hybrid, was less environmentally responsible than a Hummer SUV. How could this be? You might want consider using the AT&T Environmental Assessment Matrix in addressing this question.

> What would the business model look like if we were to compete primarily on environmental sustainability?

> Why does the concept of “cradle to grave” no longer make business and environmental sense?

> Using a SWOT analysis, can the operations management system be a strength? Can the operations management system be a weakness? Provide examples.

> Have you ever stayed at an Air BnB? If so, why? To what extent was your decision influenced by the price, the location, or the experience that the Air BnB offered?

> Have you ever used social media to decide what products to buy or even where to go for a vacation? Provide some examples. Have negative reviews on social media ever caused you to avoid buying a certain product? Why?

> How could the Internet of Things affect such activities as you visiting a store to buy a product?

> Recently, companies such as Verizon, Automatic, and Zubie have introduced a module that plugs into the diagnostic port of most cars. This module keeps track of the status of the car and informs the user of any problems (explaining the problems in plain E

> Review the new strategic direction for Unilever, as presented at the beginning of this chapter. What are the economic rationales for these seven key strategic imperatives? What are the risks? To what extent are these initiatives driven by concerns of env

> What are the differences between a project objective statement, a project charter, and a project business case?

> What strengths do you possess that would make you an excellent project manager? In what areas do you need to improve?

> Suppose that you are the leader of a project aimed to quickly develop and explore radical new business opportunities that exploit the company’s strengths in supply chain management. What types of personnel would you want on your team? How would you organ

> At what point in the life of a project does the project manager have the greatest ability to influence the success of the project? Name three things you would try to get executive sponsors of a project to agree to before you accepted the job as project m

> Think of the last project in which you participated that did not go as well as planned (e.g., this could be a team assignment for a class). Were the causes of failure mainly social or technical in nature? Explain.

> In this chapter, you were introduced to Huffy Bicycles. You were also told that the critical customers were store managers and purchasing managers. Now, assume that Huffy decided to target first parents and then children as their critical customers (usin

> What are some of the assumptions underlying the critical path method (CPM)? Can you think of situations in which the CPM assumptions would not be valid?

> What impact will a supplier’s quality and delivery problems have on a company using MRP? Why?

> How do L4L, FOQ, and POQ ordering policies impact set-up/ordering costs and inventory costs? Why?

> As an organization increases its level of outsourcing, what will be the impact on its bill of materials? Why?

> What problems can MRP create for suppliers as you go upstream in the supply chain? Why?

> What types of companies are likely to benefit the most from using MRP? Why?

> What is the relationship between cumulative lead time and changes in the MPS? Why?

> The planning process involves a rolling time horizon. What does this mean to a planner?

> Why is collaboration within an organization and the supply chain important when using DRP and MRP?

> How have advances in computer technology changed the planning process? Why? What changes do you expect in the future?

> Elm Furniture Company, a medium-sized, publicly traded manufacturer of wood-based office and home furniture systems, has agreed that its major goal should be to “Become recognized as a value and social leader in the wood furniture industry.” Consistent w

> In what ways are DRP and MRP similar and how are they different?

> Why are spare parts and service parts considered to be independent demand, not dependent demand?

> In one of this chapter’s “Get Real” stories, you read about the experiences of Nintendo in planning production of its Switch system. If you were on the aggregate planning team for the Switch, would you plan for average demand or for peak demand, and why?

> In most companies that are considered to be successful users of the S&OP process, the resulting plans and commitments are treated, essentially, as “quasi-contracts.” That is, the agreement reached between the various parties cannot be unilaterally broken

> If most aggregate production planning problems include assumptions and ignore many needs of the company that are difficult to quantify, then what is the benefit of the process?

> Explain why the following is not necessarily a true statement: “If a company is chasing demand, then it is overinvesting in balance-sheet assets since inventories will be high.”

> Suppose your firm is using a level production planning approach to manage a seasonal demand. Your production manager is evaluated on lowest production cost but the logistics manager is evaluated on the amount of inventory the firm holds. Explain the issu

> What are the key cost advantages of level production strategy over a chase strategy? Of a chase strategy over a level production strategy?

> Do you think chase strategies might be more appropriate in some industries than in others? Give some examples and explain why.

> Explain in your own words the typical differences in objectives for production managers and sales managers.

> As North American firms increasingly turn to product innovation, the management and protection of Intellectual Property becomes an important issue. Discuss how intellectual property considerations can affect such areas in supply chain strategy as: a. Sup

> What is the value of the S&OP process to an organization? Why should it be a dynamic process rather than a one-time annual event?

> What arguments would you use in order to justify tightening the limits used on a tracking signal control chart? How about for loosening the limits?